The California Institute for Regenerative Medicine (CIRM) is driving conversations and collaboration to address the manufacturing challenges of cell and gene therapies (CGT).

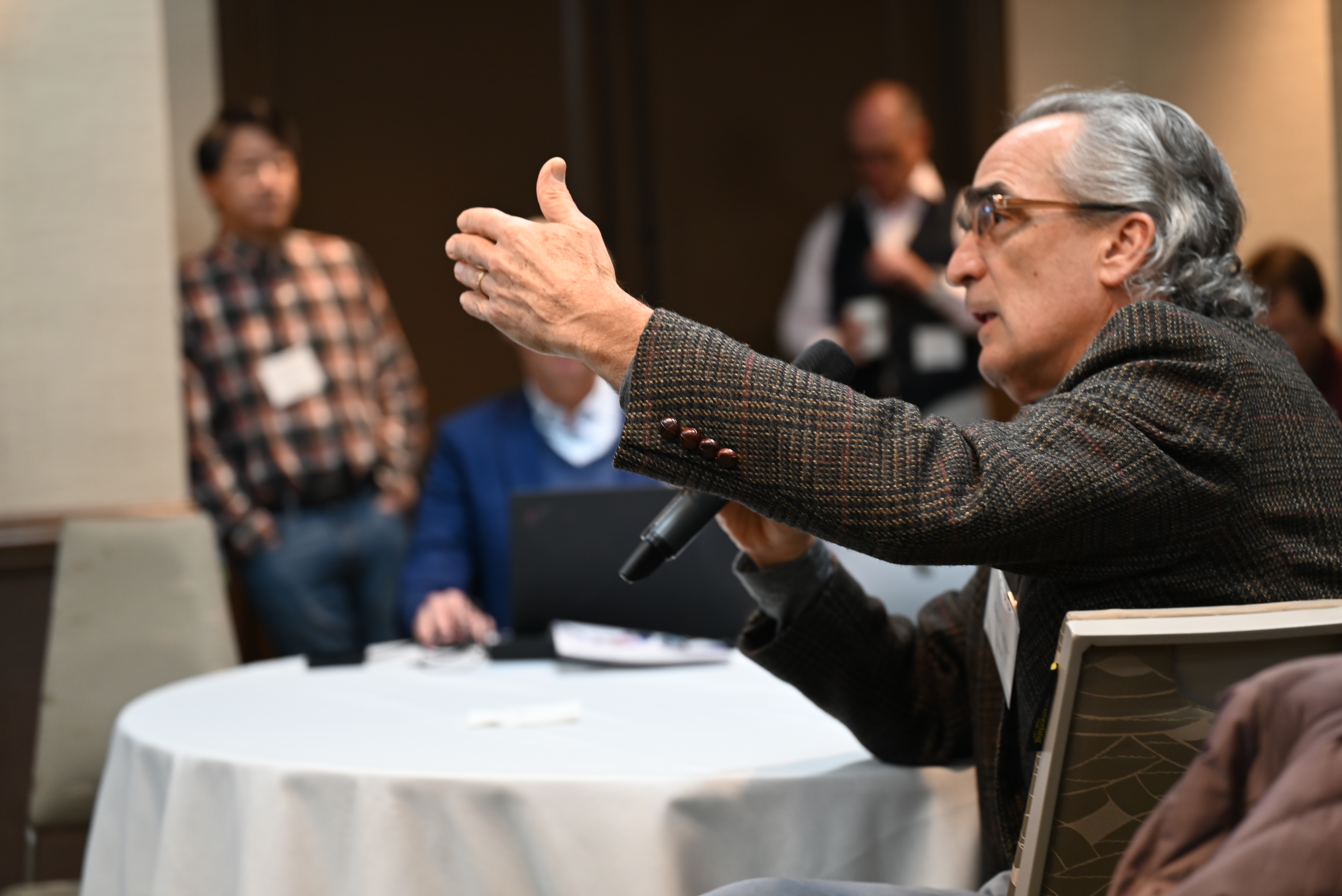

CIRM hosted its inaugural Manufacturing Network Symposium in South San Francisco, bringing together more than 100 experts and stakeholders from the regenerative medicine field, including scientific leaders from academic institutions, private contract development and manufacturing organizations (CDMOs), and numerous researchers.

The event was made possible with support from sponsors Forge Biologics and Avid Bioservices, whose commitment to advancing cell and gene therapy manufacturing helped foster these critical discussions.

A Focus on Patients and Collaboration

The event was kicked off with opening remarks by CIRM’s President and CEO Jonathan Thomas, PhD, JD, and Associate Vice President of Preclinical Development Shyam Patel, PhD, both stressing the importance of collaborative events like the Symposium.

Brian Shy, MD, PhD, Director of the Investigational Cell Therapy Program at UCSF, shared insights into ongoing manufacturing projects at UCSF facilities. He emphasized that the ultimate goal of their work is to enable patients to live normal lives. A key theme in his discussion was the importance of collaboration—rather than duplicating efforts, institutions should work together to drive progress. When asked about accessibility and reimbursement, he acknowledged these as critical considerations in bringing therapies to more patients.

Aileen Anderson, PhD, Director at the Sue and Bill Gross Stem Cell Research Center at UC Irvine, and Brian Fury, MS, Director of the Gene Therapy Center at UC Davis, highlighted successful collaborations between their institutions, including UC Davis’ role in supporting UC Irvine in designing and building its Good Manufacturing Practice (GMP) facility. They also addressed challenges when working across institutions, such as perceived competition and the need for standardization.

Partnering with Industry

Taby Ahsan, PhD, VP of Cell Therapy Operations at City of Hope, emphasized the need to stabilize the CGT field and California’s role in leading this effort. She noted that partnerships with industry face challenges such as extended contracting periods, intellectual property ownership issues, and shifting priorities.

However, institutions like City of Hope are leveraging their strengths—such as expertise in early-phase trials for cancer and diabetes—to move the field forward.

Case Study: Duke University’s Robertson GMP Lab

Beth Shaz, MD, director of the Robertson GMP laboratory and co-director of Duke University’s Stem Cell Lab, shared a case study on how Duke’s GMP Lab successfully translated academic research into patient therapies.

One notable success story involved the development of a treatment for congenital athymia in patients with DiGeorge Syndrome. Duke has received FDA approval for the therapy, with 32 patients treated. The challenge ahead is expanding access beyond Duke to other partnering facilities.

Dr. Shaz underscored the vital role of academic medical centers in bringing new therapies to patients and called for new models that improve access to expensive and rare disease treatments.

Case Study: Lonza’s Approach to CGT Manufacturing

Krishna Panchalingam, PhD, Associate Director of CGT Account Management at Lonza, provided an industry perspective on CGT manufacturing, focusing on optimizing processes for delivery.

When asked about the future of automation and robotics, he noted that these technologies will play an increasing role in scaling up CGT manufacturing.

Breakout Sessions: Building a Stronger Manufacturing Ecosystem

The second half of the event featured breakout discussions that emphasized the importance of collaboration among institutions, industry, and government to tackle CGT manufacturing challenges.

Key takeaways included the need to standardize processes, address infrastructure gaps, and enhance partnerships to ensure that groundbreaking therapies reach the patients who need them.

How CIRM is Paving the Way for Progress in CGT Manufacturing

In 2023, CIRM made an initial investment of $18 million across nine grants as part of the first phase to establish the California CGT Manufacturing Network. The network aims to eliminate manufacturing bottlenecks that have hindered the development and approval of regenerative medicine therapies.

“This investment is a critical first step in the formation of the manufacturing network and will help California academic GMP manufacturing facilities raise the quality and competency of CGT manufacturing across the state,” says Shyam Patel, PhD, Associate Vice President of Preclinical Development at CIRM.

With nine state-of-the-art GMP facilities located across the state, the network aims to bridge the gap between early-stage research and clinical application. By supporting the development of robust, scalable manufacturing solutions, CIRM is accelerating the path to bringing life-changing therapies to the people who need them most.